High Pressure Brass Pipe Fittings for Industrial Use

High pressure brass pipe fittings are essential components in modern plumbing and industrial systems. As industries evolve and demand for reliability increases, these fittings offer unmatched durability and adaptability. In this guide, you’ll explore their significance, applications, installation tips, and future prospects for using high pressure brass pipe fittings efficiently.

Understanding the Fundamentals

High pressure brass pipe fittings are connectors used to join two or more pipes carrying fluids under high pressure. These fittings are known for their strength, corrosion resistance, and versatility. Over the decades, they have replaced other materials in many industries due to their superior performance.

Grasping the basic principles behind brass fittings is vital for both new installers and seasoned professionals. These principles help ensure long-term system stability, efficiency, and safety under pressure.

1.1 Material Composition and Strength

Brass, an alloy of copper and zinc, provides a perfect blend of flexibility and toughness. It’s highly resistant to corrosion, especially when exposed to water, oils, and various chemicals. This makes it an ideal material for fittings used in demanding environments like industrial plumbing and hydraulic systems.

Real-world applications include oil and gas plants, marine systems, and chemical processing units. Common myths suggest brass can’t handle pressure, but these fittings are engineered for high-stress conditions.

1.2 Thread Types and Compatibility

Threading plays a pivotal role in fitting performance. Common thread types include NPT (National Pipe Thread) and BSP (British Standard Pipe), each serving different regional and industrial standards.

Proper matching of threads ensures a leak-proof seal. For instance, combining an NPT fitting with a BSP-threaded pipe without an adapter can lead to failures. Therefore, knowing the difference is crucial when planning installations with high pressure brass pipe fittings.

Practical Implementation Guide

Now that the foundational concepts are clear, it’s time to understand how to practically implement high pressure brass pipe fittings. Successful application hinges on precision, planning, and adherence to safety standards. The steps below provide a reliable path to proper installation and maintenance.

2.1 Actionable Steps

- Choose the Right Fitting: Select fittings based on pipe size, pressure rating, and fluid type. Use manufacturer guides to match specifications.

- Prepare the Pipe Ends: Clean and deburr all pipe ends. Apply thread sealant or Teflon tape for threaded connections.

- Secure and Test: Use torque wrenches to tighten fittings to recommended specs. Conduct a pressure test before commissioning the system.

2.2 Overcoming Challenges

Common issues include thread mismatches, over-tightening, and sealant misuse. These can lead to leaks or even system failure. To avoid this:

- Always verify thread type before assembly.

- Do not overtighten—this can deform the fitting.

- Use PTFE tape only on male threads and avoid excessive wrapping.

Experts recommend double-checking alignment and applying a secondary sealant for critical systems. This adds redundancy to high pressure installations using brass pipe fittings.

Advanced Applications

For professionals looking to go beyond the basics, advanced uses of high pressure brass pipe fittings include integration into multi-pressure systems and automation. These applications demand a deeper understanding of flow dynamics and system design.

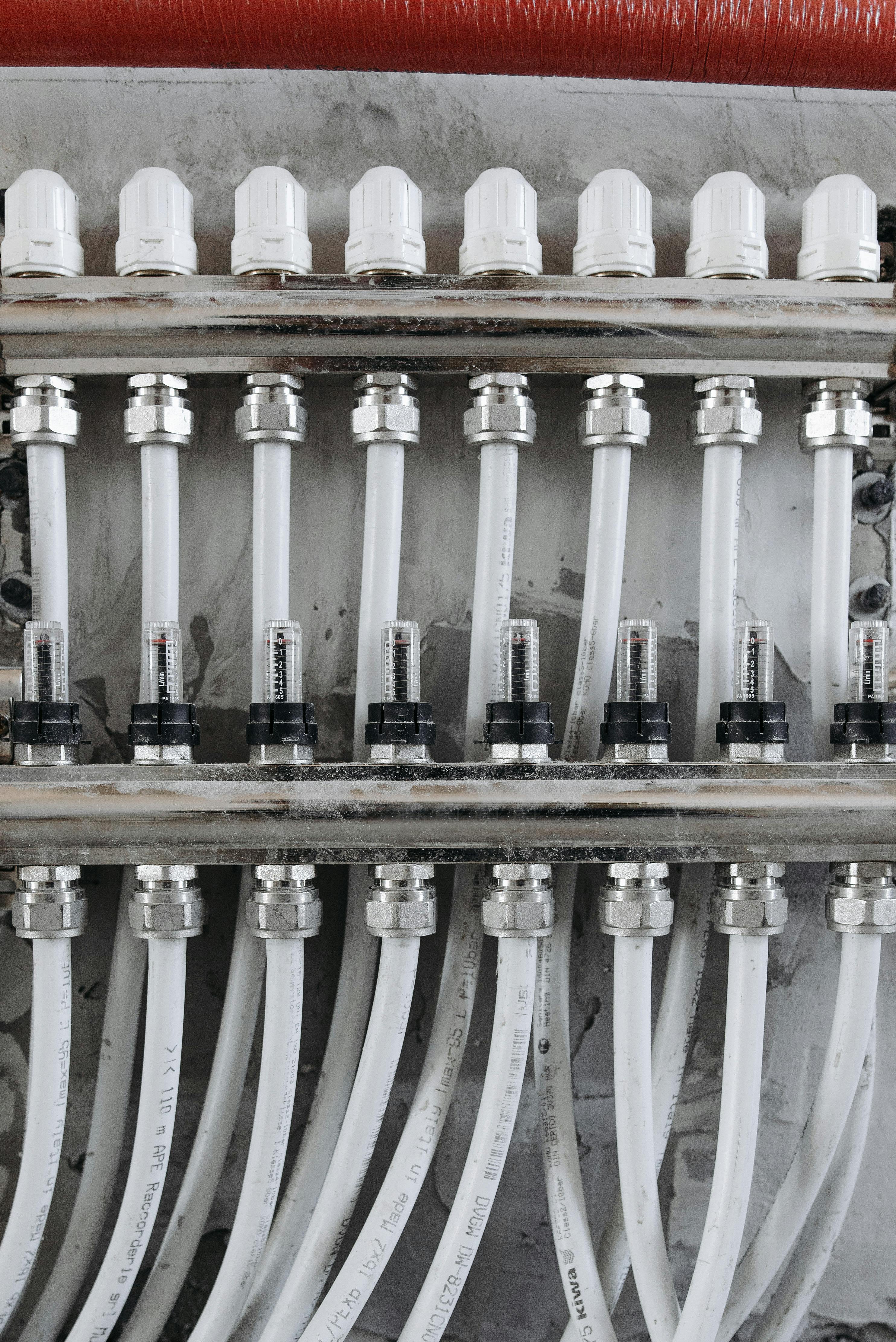

3.1 Multi-Point Distribution Networks

In complex industrial layouts, brass fittings can distribute fluids from a single source to multiple endpoints. A case study in a chemical manufacturing facility showed a 30% increase in efficiency by switching to modular brass tee fittings over steel counterparts.

Performance indicators such as flow rate, pressure drop, and system uptime were significantly improved—validating the use of brass in high-tech environments.

3.2 Integration with Sensors and Valves

Modern systems often require real-time monitoring. High pressure brass pipe fittings can be integrated with pressure gauges, flow sensors, and smart valves for automation.

Brass’s conductivity and durability make it compatible with electronic components without interference. This helps bridge mechanical systems with digital technologies effectively.

Future Outlook

With the rise of smart plumbing and sustainable construction, high pressure brass pipe fittings are set to evolve. Manufacturers are already experimenting with eco-friendly alloys and 3D-printed prototypes for complex geometries.

Over the next 3–5 years, expect to see more sensor-integrated fittings, improved corrosion-resistant coatings, and widespread use in green building initiatives. Professionals should stay informed and trained to adapt to these innovations.

Conclusion

To summarize, high pressure brass pipe fittings are reliable, versatile, and increasingly essential in industrial and residential applications. Key takeaways include their material benefits, practical application steps, and advanced use cases.

Whether you’re upgrading existing infrastructure or starting from scratch, integrating these fittings ensures safety, longevity, and efficiency. Begin by reviewing your system specs and selecting the right fittings today to future-proof your setup.

Frequently Asked Questions

- Q: What are high pressure brass pipe fittings? High pressure brass pipe fittings are components used to connect pipes carrying pressurized fluids. They offer durability and leak resistance.

- Q: How do I start using brass fittings in my plumbing system? Start by identifying the correct pipe size and pressure requirements, then select matching brass fittings from trusted suppliers.

- Q: How long does it take to install a system using brass pipe fittings? A small residential system might take a few hours, while larger industrial systems can take days depending on complexity.

- Q: Are brass fittings expensive? Brass fittings are moderately priced. Costs vary from $2 to $25 per unit depending on size, pressure rating, and design.

- Q: How do brass fittings compare to stainless steel? Brass is easier to work with and cost-effective, but stainless steel offers higher tensile strength. Brass is ideal for most general applications.

- Q: Are these fittings hard to install? With basic plumbing skills, brass fittings are straightforward to install. A bit of training goes a long way.

- Q: Can brass fittings be used in food processing industries? Yes, as long as they meet FDA or NSF standards. They are often used in beverage and dairy systems.