Everything You Need to Know About Hydraulic 90 Degree Fittings

Hydraulic 90 degree fittings are crucial components in countless fluid systems. Their role in optimizing space and ensuring smooth directional flow has made them indispensable in modern hydraulic engineering. In this article, you’ll learn the fundamentals, implementation strategies, advanced use cases, and much more to fully understand these fittings’ role and value.

Understanding the Fundamentals

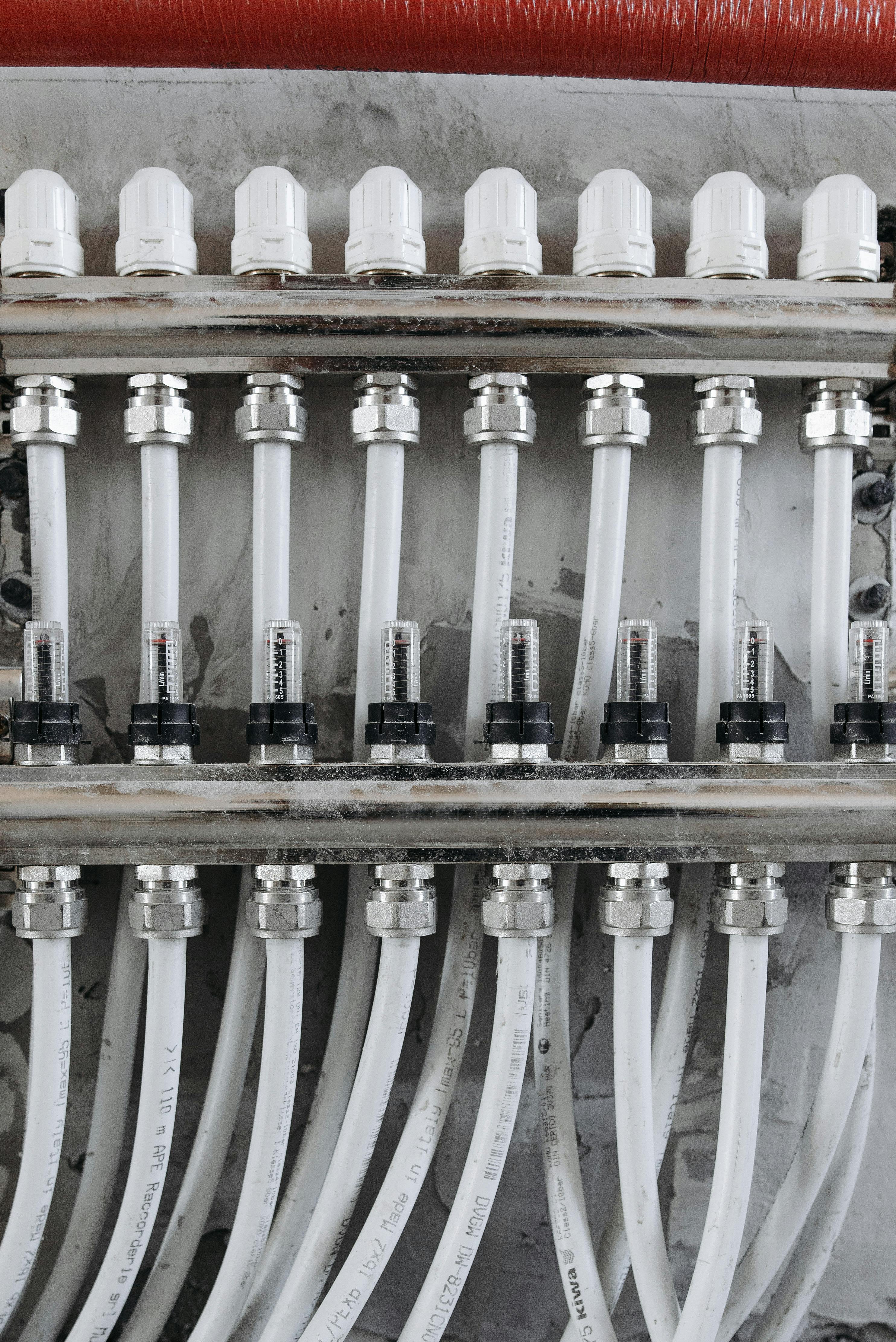

Hydraulic 90 degree fittings are angled adapters used to change the direction of fluid flow in tight or confined spaces. They are often used in hydraulic systems where linear alignment isn’t feasible. These fittings help ensure efficiency and reliability in operations ranging from industrial machinery to agricultural equipment.

Over time, the design and materials of hydraulic fittings have evolved significantly to meet growing industrial demands. Their flexibility and robustness make them a top choice for engineers and technicians worldwide.

1.1 What Are Hydraulic 90 Degree Fittings?

These are L-shaped connectors that join two segments of hydraulic hose or tubing at a right angle. They are commonly made from stainless steel, brass, or carbon steel and are designed to withstand high-pressure environments.

Common applications include:

- Construction machinery

- Automotive power steering systems

- Heavy-duty agricultural tools

They are especially helpful when the design requires a tight turning radius or limited space.

1.2 Types and Variants

There are various types of 90 degree hydraulic fittings including:

- JIC (Joint Industry Council) fittings

- ORB (O-Ring Boss) fittings

- BSP (British Standard Pipe) elbows

- NPT (National Pipe Tapered) elbows

Each type offers unique benefits depending on sealing methods, pressure ratings, and system compatibility.

Understanding these distinctions can help prevent costly leaks and performance issues, ensuring the hydraulic system remains efficient and safe.

Practical Implementation Guide

Applying the knowledge of hydraulic 90 degree fittings involves both planning and execution. Knowing when and how to use these components can significantly improve your system’s performance and longevity.

2.1 Actionable Steps

- Assess System Requirements: Determine pressure, temperature, and flow characteristics to choose the correct fitting.

- Select Proper Material: Use stainless steel for corrosive environments, brass for moderate needs, and carbon steel for strength.

- Measure and Cut: Ensure hoses and tubes are precisely measured for optimal fit and function.

2.2 Overcoming Challenges

Common obstacles include:

- Incorrect Sizing: Leads to leaks or inefficient flow

- Poor Material Selection: Results in corrosion or fatigue

- Improper Installation: Causes pressure drops or system failure

To overcome these, always consult manufacturer guidelines, use torque wrenches, and conduct pressure tests post-installation.

Expert tip: Always double-check O-ring conditions before sealing—degraded seals are a top cause of hydraulic failure.

Advanced Applications

For seasoned professionals, hydraulic 90 degree fittings open doors to sophisticated system designs. They can be used for compact power units, mobile hydraulics, and even aerospace applications where precision is vital.

3.1 Custom Hydraulic Routing

Advanced users often rely on these fittings for custom hydraulic routing. This is essential in systems where spatial constraints and high vibration exist. A recent case study showed that optimized routing using 90 degree elbows improved flow efficiency by 18%.

3.2 Integrating Smart Monitoring

Some systems now integrate sensors and monitoring tools directly onto or near fittings. This allows real-time pressure and temperature checks, enabling predictive maintenance strategies. Compatibility with IoT platforms is a growing advantage.

Future Outlook

The demand for hydraulic 90 degree fittings is expected to grow in sectors like electric vehicles and smart agriculture. Innovations in materials—such as polymer composites—are promising lighter, more corrosion-resistant options.

Staying updated on evolving fitting technologies and compliance standards will keep businesses ahead of the curve in both performance and safety.

Conclusion

To recap, hydraulic 90 degree fittings:

- Provide efficient directional changes in fluid systems

- Improve space management and system compactness

- Offer durability under high-pressure conditions

They remain a cornerstone of hydraulic system design.

Consider evaluating your existing system for optimization opportunities using hydraulic elbows. Consult a hydraulic specialist to determine what upgrades may yield the best results.

Frequently Asked Questions

- Q: What is a hydraulic 90 degree fitting? A hydraulic 90 degree fitting is an elbow-shaped connector that redirects fluid flow at a right angle within a hydraulic system.

- Q: How do I get started with hydraulic fittings? Begin by assessing your system’s pressure, flow, and layout, then consult with a supplier or technician for the appropriate fittings.

- Q: How long does installation take? Basic installations can take 30 minutes to 1 hour depending on system complexity and accessibility.

- Q: How much do hydraulic 90 degree fittings cost? Prices range from $5 to $50+ depending on material, size, and brand.

- Q: How do they compare to straight fittings? 90 degree fittings save space but may introduce minor flow resistance compared to straight connectors.

- Q: Are they hard to install? Installation is straightforward with the right tools, but proper torque and alignment are essential.

- Q: Can I use them in agriculture? Absolutely. They are widely used in tractors, harvesters, and irrigation systems where maneuverability is crucial.