Comprehensive Guide to Hydraulic Bulkhead Fitting

Hydraulic bulkhead fittings are an essential component in modern fluid systems. They allow secure, leak-proof passage of hydraulic lines through equipment walls or panels. As industries advance and machinery grows more complex, understanding these fittings becomes increasingly important. In this guide, you’ll discover the function, design, implementation, and future of hydraulic bulkhead fittings — all in one place.

Understanding the Fundamentals

At their core, hydraulic bulkhead fittings enable the transfer of hydraulic fluid through a barrier such as a tank or wall while maintaining system integrity. These components are especially critical in high-pressure environments, offering both durability and sealing capabilities.

Originally developed for aerospace and military applications, bulkhead fittings have since evolved for use in construction, agriculture, and industrial machinery. Their ability to maintain fluid control across structural boundaries makes them indispensable in complex hydraulic networks.

1.1 What Is a Hydraulic Bulkhead Fitting?

A hydraulic bulkhead fitting is a type of connector designed to pass through a fixed barrier and create a sealed joint. These fittings consist of a threaded body, locknut, and seal to prevent leakage. They are often made from stainless steel, brass, or high-strength polymers.

In real-world applications, these fittings are found in everything from bulldozers and cranes to wind turbines and submarines. Many assume they are interchangeable with standard connectors — a common misconception. Their unique design allows them to anchor securely across structural components.

1.2 Key Characteristics of Bulkhead Fittings

Compared to standard hydraulic fittings, bulkhead fittings offer unique structural anchoring. They create a rigid interface that reduces stress on hoses and tubing.

Bulkhead fittings also support both low and high-pressure systems. Their design typically includes an O-ring or elastomer seal, providing excellent leak resistance in dynamic environments. These qualities are especially valuable in mobile equipment that experiences vibration or shifting loads.

Practical Implementation Guide

Understanding the theory is just the beginning. Now let’s dive into how you can integrate hydraulic bulkhead fittings into your own fluid systems. Whether you’re building new machinery or upgrading an existing setup, practical execution is key to achieving long-lasting performance.

2.1 Actionable Steps

- Identify Panel Thickness and Material: Measure the surface through which the bulkhead will pass and choose the correct thread length and body material.

- Select the Correct Fitting Type: Choose from straight, elbow, or tee bulkhead fittings based on system layout and fluid direction.

- Install with Proper Torque: Use a torque wrench to tighten fittings according to manufacturer specifications. This ensures seal integrity without damaging threads.

2.2 Overcoming Challenges

Implementing bulkhead fittings isn’t without its challenges. Some common issues include:

- Improper sealing due to damaged O-rings

- Incorrect fitting size leading to leaks

- Excessive torque damaging the panel

To avoid these problems, always inspect components before installation, follow torque guidelines, and verify thread compatibility. Experts also recommend using thread sealants where appropriate to enhance leak protection in high-pressure environments.

Advanced Applications

Once you’ve mastered the basics, you can explore more advanced applications of hydraulic bulkhead fittings. These include integration with automation systems, modular hydraulic panels, and multi-fluid routing setups.

3.1 Modular System Integration

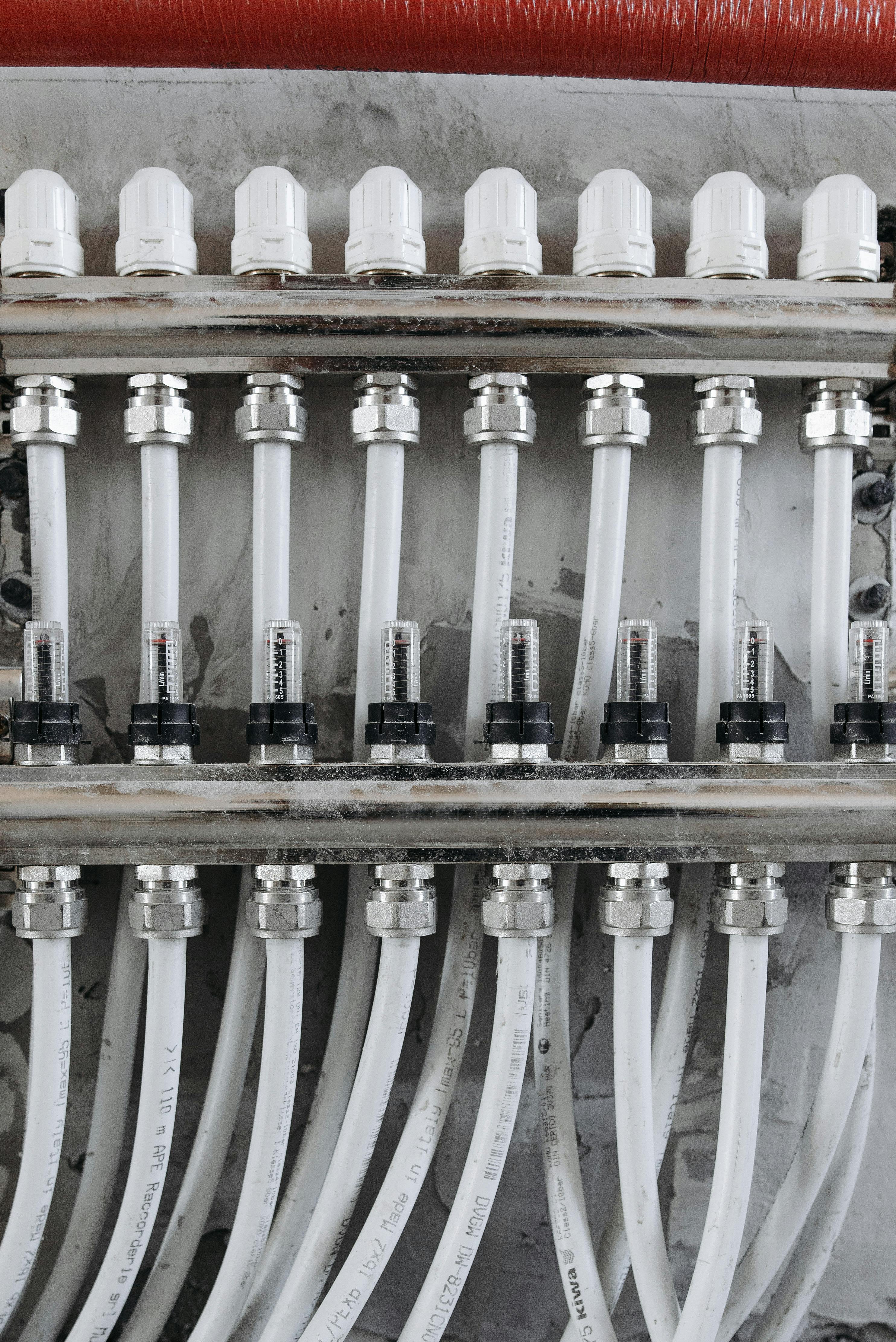

Advanced facilities use modular hydraulic panels that allow quick change-outs and reconfiguration. Bulkhead fittings serve as the gateway points for these modular setups, enabling flexible connections that support rapid maintenance and upgrades.

Case studies in aerospace manufacturing show that using modular bulkhead panels reduced system downtime by over 30%, boosting productivity while ensuring safety.

3.2 Automation and Sensor Coupling

Modern hydraulic systems increasingly integrate sensors and automation. Bulkhead fittings must accommodate these add-ons without compromising flow or pressure. Compatible fittings with integrated ports for pressure gauges or sensors allow real-time monitoring.

This integration is especially beneficial in robotic arms, CNC machines, and automated assembly lines, where fluid precision translates directly to accuracy and efficiency.

Future Outlook

The future of hydraulic bulkhead fittings looks promising with the rise of smart manufacturing and Industry 4.0. Materials are becoming lighter and stronger, while fitting designs evolve to support higher pressures and advanced sealing mechanisms.

Over the next 3–5 years, we expect to see growth in self-monitoring fittings, integrated IoT sensors, and environmentally friendly sealing materials. Readers looking to stay ahead should invest in versatile, upgradeable systems that adapt to emerging technologies.

Conclusion

Hydraulic bulkhead fittings are far more than simple connectors. They serve a vital role in fluid management, offering safety, reliability, and flexibility. From selecting the right fitting to mastering installation and exploring advanced systems, the knowledge you gain here can drastically improve your hydraulic setup.

Ready to take your hydraulic systems to the next level? Begin by evaluating your current layout and identifying where bulkhead fittings can improve efficiency and safety. Whether you’re a technician or an engineer, now is the time to optimize.

Frequently Asked Questions

- Q: What is a hydraulic bulkhead fitting? A hydraulic bulkhead fitting allows fluid lines to pass through walls or barriers while maintaining a leak-proof seal.

- Q: How do I get started with bulkhead fittings? Start by identifying where you need secure wall penetrations in your hydraulic system and selecting the appropriate fitting type.

- Q: How long does it take to install one? Installation can take 10–30 minutes depending on access and preparation, though complex systems may take longer.

- Q: How much do bulkhead fittings cost? Prices range from $10 to $100+ depending on material, size, and pressure rating.

- Q: How do bulkhead fittings compare to standard fittings? Bulkhead fittings are designed for fixed barrier penetration and offer superior anchoring and sealing in such applications.

- Q: Are they difficult to install? Not particularly, but proper sizing and torque application are critical for success. A moderate skill level is sufficient with the right tools.

- Q: Can they be used in the marine industry? Absolutely. They are commonly used in boats and submarines to route hydraulic lines through watertight bulkheads.