Everything You Need to Know About Hydraulic Fitting Caps

Hydraulic fitting caps may seem like minor components, but they play a crucial role in protecting your hydraulic systems. In today’s high-performance industrial environments, ensuring proper sealing and protection of fluid connections is more important than ever. In this comprehensive guide, you’ll discover everything from the basics of hydraulic fitting caps to advanced applications, ensuring optimal performance and system longevity.

Understanding the Fundamentals

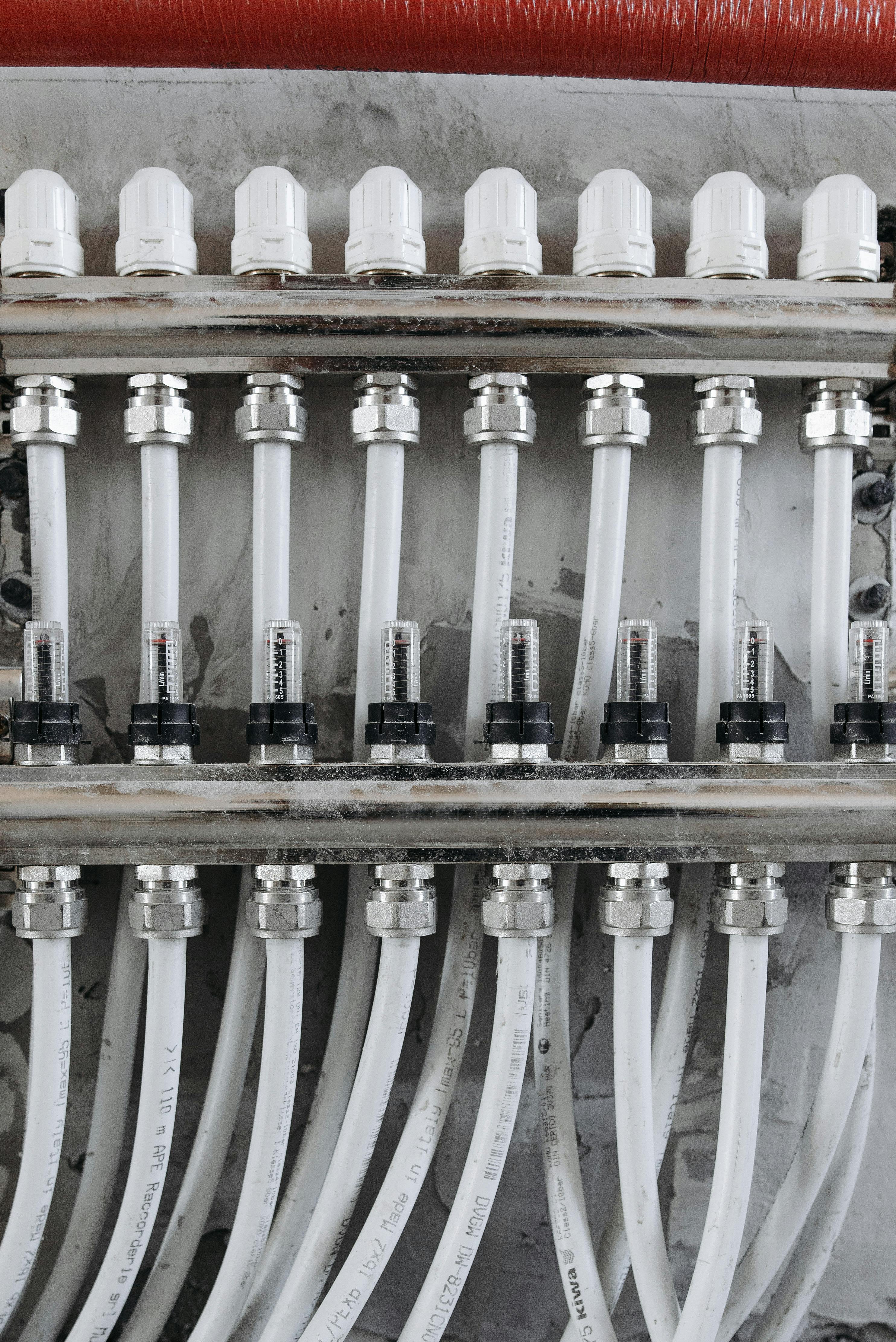

Hydraulic fitting caps are specialized covers designed to protect the ends of hydraulic hoses, pipes, and fittings from dust, debris, and damage. Their primary function is to preserve the integrity of hydraulic systems when connections are not in use. Over the years, they’ve evolved from simple plugs to engineered components built for high-pressure applications.

Mastering the fundamentals of hydraulic caps helps prevent contamination, reduce maintenance downtime, and extend equipment life. Think of them as protective armor for the lifelines of your machinery — small yet essential for smooth operation.

1.1 What Are Hydraulic Fitting Caps?

Hydraulic fitting caps are threaded or push-fit covers that seal open ends of hydraulic components. They prevent ingress of dust, moisture, or contaminants, especially during transportation or storage. These caps come in a range of materials including plastic, brass, and stainless steel, each tailored to specific conditions.

Real-world applications include capping off unused ports in an excavator, protecting hose fittings during shipping, or preventing leaks during repair work. A common misconception is that these caps are optional — however, leaving ports uncapped can result in costly contamination and pressure failures.

1.2 Types and Materials of Hydraulic Caps

There are several types of hydraulic fitting caps: threaded caps, push-on caps, flange caps, and quick-connect caps. Each has its own application, suited for either temporary sealing or long-term protection. Threaded caps offer superior pressure sealing, while push-on caps provide quick and easy solutions.

Plastic caps are cost-effective and corrosion-resistant, ideal for short-term use. Metal caps, on the other hand, withstand extreme temperatures and pressures, making them perfect for heavy-duty systems. Choosing the right cap type ensures system efficiency and safety.

Practical Implementation Guide

Now that the basics are covered, let’s look at how to implement hydraulic fitting caps into your operations effectively. A well-thought-out implementation can significantly reduce maintenance issues and enhance system reliability.

2.1 Actionable Steps

- Inspect Connections: Examine all hydraulic ports and hoses for signs of wear or contamination before capping.

- Select the Right Cap: Choose based on material compatibility, pressure rating, and exposure conditions.

- Install Properly: For threaded types, ensure snug fit using hand torque. For push-fit caps, verify complete insertion.

2.2 Overcoming Challenges

Common obstacles include using the wrong cap material, which can melt or degrade under heat. Improper sealing can also result in pressure leaks. Another issue is misidentifying cap sizes, leading to poor fit and system exposure.

To troubleshoot, keep a sizing chart handy and always double-check part specifications. Expert tip: store caps in a labeled, clean container to avoid contamination before installation.

Advanced Applications

Beyond basic sealing, hydraulic fitting caps also serve in diagnostic and system tuning operations. These advanced applications improve system accuracy and help monitor performance under varying conditions.

3.1 Pressure Testing and Calibration

In advanced fluid systems, fitting caps are used to isolate sections for pressure testing. Technicians install high-pressure rated caps to simulate system load and test for leaks, flow consistency, and pressure stability. Industries like aerospace and energy rely heavily on this application for safety compliance.

3.2 Integration with Smart Systems

Modern smart hydraulics often require components that integrate with sensors. Some hydraulic fitting caps now feature embedded RFID or QR tagging for inventory tracking and maintenance scheduling. This seamless integration improves asset management and reduces human error.

Future Outlook

The hydraulic industry is witnessing a rise in automation and IoT integration, and fitting caps are evolving too. Trends point toward smart, self-monitoring caps that detect temperature changes and pressure variations in real time.

Over the next 3-5 years, we expect materials like bio-based plastics and shape-memory alloys to revolutionize cap design. Businesses should prepare by upgrading to systems compatible with these innovations and training staff accordingly.

Conclusion

Hydraulic fitting caps are vital for protecting equipment, maintaining performance, and extending the life of hydraulic systems. They may be small, but their impact is significant.

To recap: Choose the right type and material, follow best practices for installation, and explore advanced uses to get the most value. Start implementing proper cap usage today for long-term reliability and efficiency.

Frequently Asked Questions

- Q: What are hydraulic fitting caps used for? They protect hydraulic system openings from contaminants and maintain pressure integrity during downtime or transport.

- Q: How do I choose the right hydraulic cap? Start by identifying thread type, pressure requirements, and environmental conditions to select the correct material and design.

- Q: How long does it take to install hydraulic caps? Most installations take less than 5 minutes, depending on accessibility and cap type.

- Q: What is the cost of hydraulic fitting caps? Prices vary from $0.50 for plastic caps to over $10 for high-performance metal versions. Bulk purchases can lower cost.

- Q: Are hydraulic fitting caps better than plugs? Caps cover the exterior of a fitting, while plugs seal the internal threads. Each has pros depending on the application.

- Q: Are they difficult to install? No, most caps are designed for tool-free installation, although high-pressure systems may require torque tools for safety.

- Q: Can I use these in marine or aviation applications? Absolutely. Choose stainless steel or corrosion-resistant versions approved for those industries to ensure safety and compliance.