Complete Guide to Hydraulic Hose Swivel Fitting

Hydraulic hose swivel fittings are essential components in modern hydraulic systems, allowing for movement without compromising pressure or fluid integrity. With growing industrial automation and the demand for flexible, high-performance equipment, understanding how swivel fittings work is more important than ever. In this guide, you’ll explore the fundamentals, learn how to implement them properly, and discover advanced applications that can optimize your hydraulic systems.

Understanding the Fundamentals

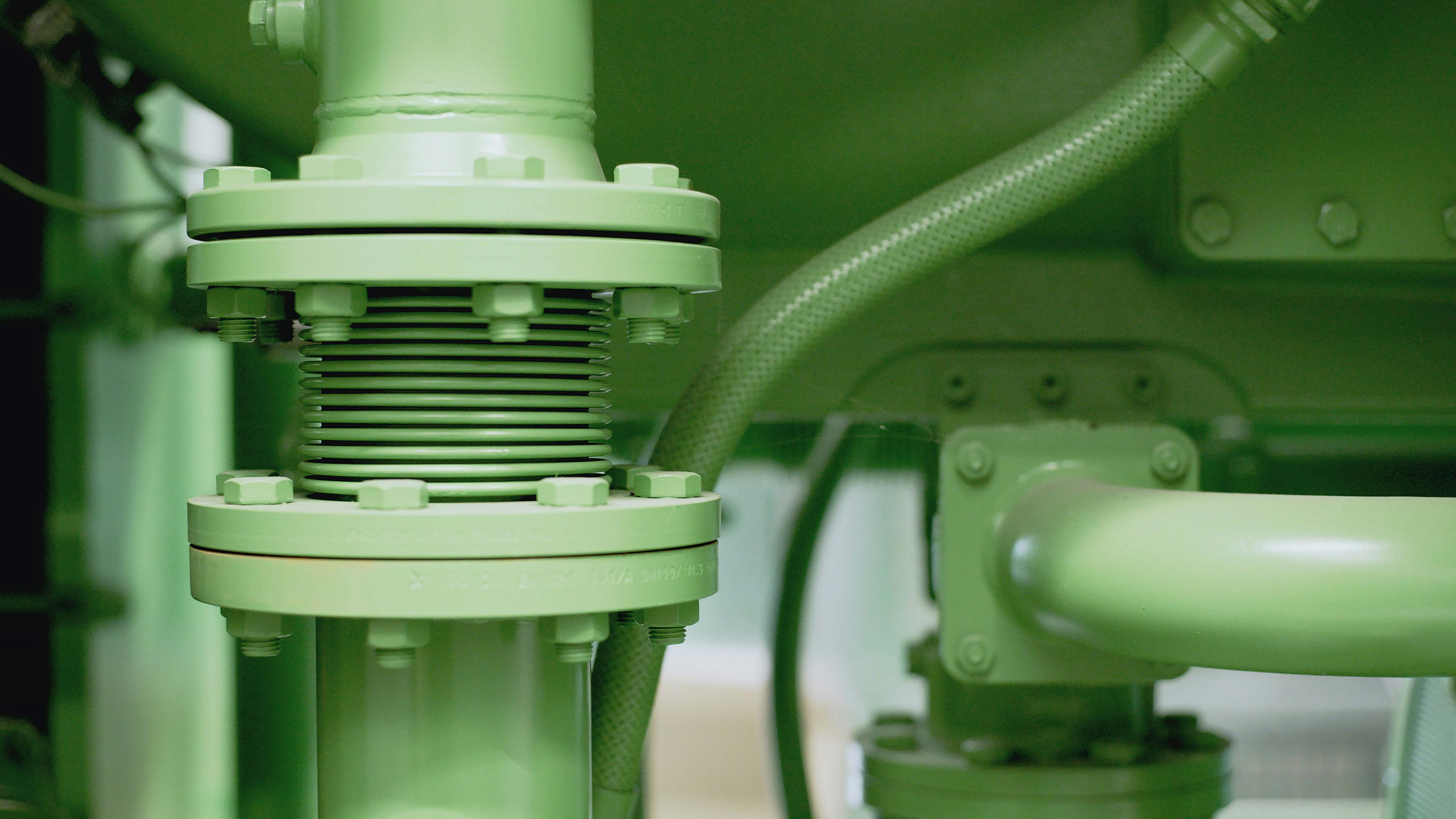

Hydraulic hose swivel fittings are specialized connectors designed to enable the rotation of hoses without twisting or tangling, which is crucial in dynamic hydraulic systems. These fittings reduce stress, enhance system durability, and improve performance over time.

Historically, fixed hose fittings dominated the market, often causing wear and rupture under motion. The invention of swivel fittings marked a significant advancement, allowing fluid connections to remain secure under rotational movement, thus boosting efficiency and lifespan.

1.1 What Are Hydraulic Hose Swivel Fittings?

These are mechanical connectors that rotate at one or more axes while maintaining a sealed, high-pressure fluid path. They are often found in applications where hoses must move continuously, such as in heavy machinery or robotics.

Swivel fittings commonly feature ball bearings or bushings that allow free rotation. Contrary to a standard hose fitting, a swivel fitting can prevent damage caused by torsion and vibration, improving overall reliability.

1.2 Types and Materials

There are multiple types of hydraulic swivel fittings, including straight swivel, 90-degree swivel, and live swivels. Each type is tailored for specific use cases, such as space constraints or directional changes.

Materials vary depending on the environment. Common materials include stainless steel for corrosion resistance, brass for moderate pressure, and carbon steel for rugged, high-pressure settings. Choosing the right material ensures optimal performance and longevity.

Practical Implementation Guide

Applying the right hydraulic hose swivel fitting can dramatically improve system performance and reduce maintenance. Implementing these components correctly ensures fluid efficiency and minimizes the risk of failure or accidents.

2.1 Actionable Steps

- Assess System Requirements: Determine the pressure rating, hose size, and movement type required. Match the fitting to the fluid type and environmental conditions.

- Select Appropriate Fittings: Choose between fixed, swivel, or live swivel fittings. Use manufacturer charts for compatibility.

- Install with Proper Torque: Avoid over-tightening. Use a calibrated wrench and follow manufacturer torque specs to avoid thread stripping or seal failure.

2.2 Overcoming Challenges

Common installation issues include incorrect thread selection, underestimating pressure ratings, and poor alignment. These mistakes can lead to leaks or premature failure.

Expert tips include using Teflon tape only where recommended, checking for burrs or dirt inside the hose, and inspecting the O-ring seals regularly. Always double-check for rotational freedom post-installation.

Advanced Applications

Beyond basic implementations, hydraulic hose swivel fittings offer advanced capabilities in precision-controlled and high-pressure environments. These are suitable for industries like aerospace, defense, and automation where movement and fluid control are critical.

3.1 Rotating Joints in Robotic Arms

In robotic applications, swivel fittings allow arms to rotate freely without twisting hydraulic lines. These setups often involve multi-axis rotation, requiring precision-manufactured live swivels with exact tolerances.

Performance metrics often exceed 3000 PSI and sustain rotational speeds of up to 30 RPM under full load. Failure in these systems can result in complete shutdown, so redundancy and high-quality parts are critical.

3.2 Integration with Centralized Systems

In centralized hydraulic systems, such as those used in mining or subsea operations, swivel fittings are used to connect multiple hoses in a modular fashion. This allows for system-wide flexibility and fast reconfiguration.

Compatibility with various hose types, including braided and spiral-wound, must be considered. Additionally, many systems now use sensor-integrated swivel fittings to monitor pressure and rotation in real time.

Future Outlook

The future of hydraulic hose swivel fittings lies in smart integration. IoT-enabled fittings with real-time diagnostics are emerging, providing predictive maintenance capabilities and reducing downtime in critical systems.

Industry projections suggest a 7% CAGR over the next five years due to increasing automation in agriculture, manufacturing, and construction. As machinery becomes more mobile and complex, the demand for high-performance swivel solutions will rise.

Conclusion

To summarize, hydraulic hose swivel fittings are vital for efficient, safe, and long-lasting hydraulic systems. Understanding their types, installation techniques, and advanced applications can significantly enhance operational reliability.

If you’re involved in hydraulic operations, start assessing your current fittings and consider upgrading to swivels where movement and pressure coexist. Invest in quality now to avoid costly failures later.

Frequently Asked Questions

- Q: What is a hydraulic hose swivel fitting? A mechanical connector that allows hoses to rotate without twisting, commonly used in dynamic hydraulic systems.

- Q: How do I get started with swivel fittings? Identify the motion requirements in your system and replace fixed fittings with appropriately rated swivel types.

- Q: How long does installation take? Basic installation takes 20–45 minutes depending on system complexity and access points.

- Q: How much do swivel fittings cost? Prices range from $10 to $150 depending on size, material, and application pressure rating.

- Q: Are swivel fittings better than fixed ones? Swivel fittings reduce wear and improve flexibility, especially in moving machinery, but cost slightly more.

- Q: Are they hard to install? Not particularly—basic mechanical skills and the right tools make installation straightforward.

- Q: Can these be used in agriculture? Yes, swivel fittings are widely used in tractors, harvesters, and irrigation systems for their durability and movement tolerance.