Complete Guide to Flat Face Hydraulic Hose Fittings

Flat face hydraulic hose fittings have become the industry standard for modern hydraulic systems. With industries moving toward safer, more efficient operations, understanding these fittings is more critical than ever. In this guide, you’ll learn what flat face fittings are, why they’re essential, and how to implement them effectively in your hydraulic systems.

Understanding the Fundamentals

Flat face hydraulic hose fittings are specialized connectors designed to eliminate fluid loss during disconnection. Unlike traditional fittings, they feature a smooth sealing surface that significantly reduces the chance of leaks and contamination.

These fittings have gained popularity due to increased safety requirements and efficiency demands across agriculture, construction, and industrial machinery sectors.

1.1 Design and Function

Flat face fittings use a push-to-connect and disconnect mechanism, making them ideal for high-pressure systems. They prevent air inclusion and oil spillage—common issues in conventional quick-connect couplings.

For example, a study in the hydraulics sector found that flat face fittings reduce fluid loss by up to 90% compared to poppet-style connectors.

1.2 Compatibility and Efficiency

Flat face hydraulic hose fittings are compatible with a wide range of fluid systems. What sets them apart is the ISO 16028 standardization, ensuring interchangeability across equipment brands.

Real-world scenarios, such as quick maintenance in field equipment, highlight their efficiency. These fittings minimize downtime and improve safety, even in high-pressure environments.

Practical Implementation Guide

Implementing flat face hydraulic hose fittings in your system is straightforward but requires attention to detail. Knowing what to expect helps avoid costly errors and maximizes the advantages of leak-free connections.

2.1 Actionable Steps

- Assess System Requirements: Determine pressure rating, fluid type, and compatibility needs before selecting fittings.

- Select Quality Components: Choose ISO 16028 certified flat face hydraulic hose fittings for optimal safety and durability.

- Installation Protocol: Follow torque specifications and ensure fittings are clean and properly aligned to avoid leaks.

2.2 Overcoming Challenges

Here are some common implementation challenges and how to overcome them:

- Improper fit: Use size charts and brand compatibility tools.

- Cross-contamination: Always cap and clean before connection.

- High pressure leaks: Recheck alignment and torque levels.

- Tool mismatch: Ensure wrenches and fittings match manufacturer guidelines.

Expert tip: Use dielectric grease to improve connection integrity in corrosive environments.

Advanced Applications

Once you’re comfortable with standard setups, advanced configurations of flat face hydraulic hose fittings allow for even more specialized applications. These advanced techniques can significantly boost performance and customization.

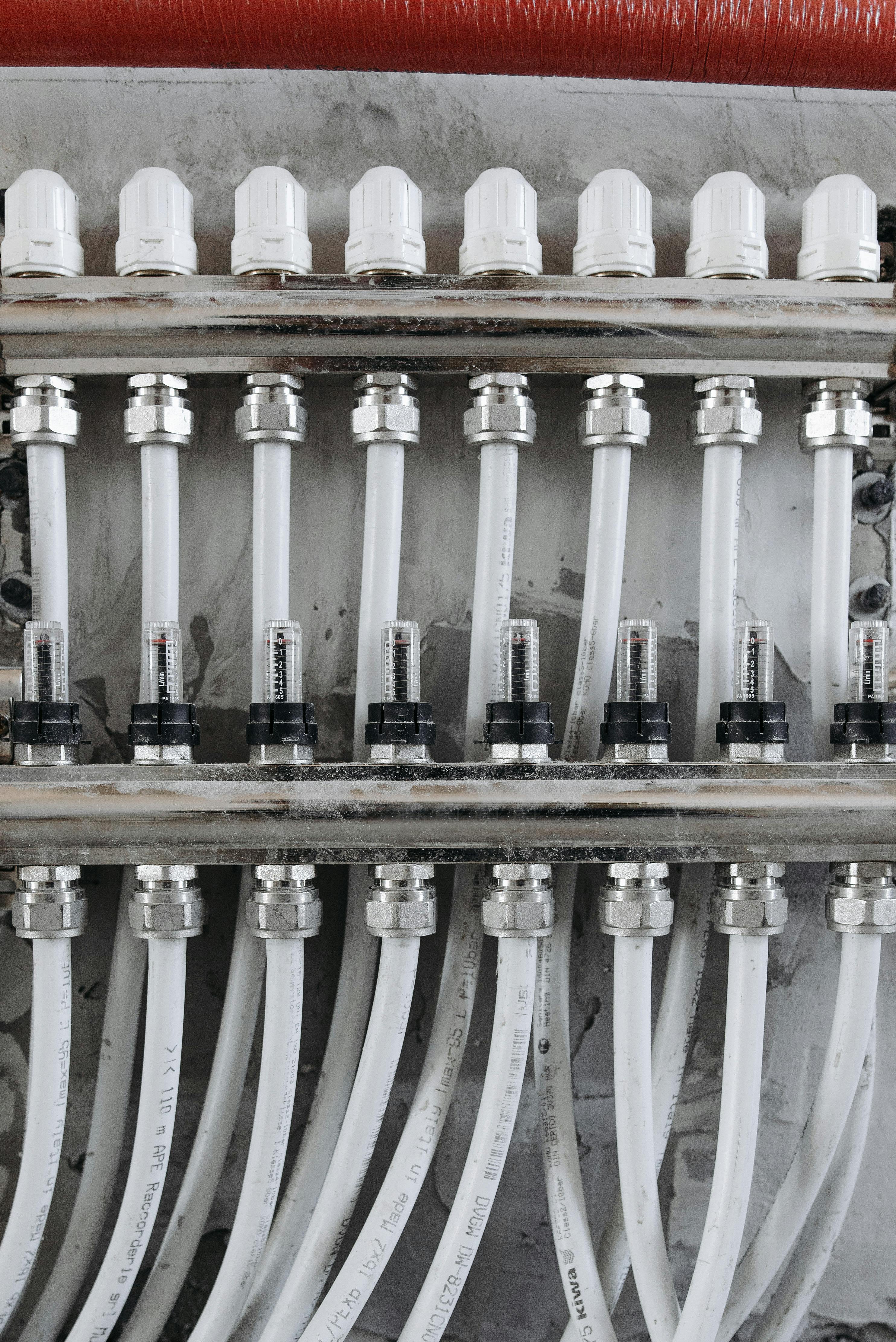

3.1 Integrated Hydraulic Manifolds

Combining flat face fittings with custom manifolds enables faster installation and modular design. Case studies in agriculture show up to 35% faster maintenance turnaround using integrated systems.

Performance metrics often include reduced pressure loss and improved fluid dynamics, ideal for precision applications.

3.2 Hybrid Coupling Systems

In certain scenarios, flat face fittings are integrated into hybrid systems alongside threaded or compression fittings. This allows for the use of multi-fluid systems, particularly in aerospace or defense applications.

However, compatibility must be double-checked—hybrid systems require careful planning to avoid mismatch and pressure failures.

Future Outlook

The demand for high-efficiency, leak-free hydraulic systems is driving innovation in flat face fitting technology. New trends include smart fittings with embedded sensors and self-locking mechanisms.

Over the next 3–5 years, expect increased automation in maintenance protocols, with AI-assisted diagnostics tied into hydraulic systems using these fittings.

Conclusion

Flat face hydraulic hose fittings are a game-changer for fluid transfer systems. Key takeaways include their superior sealing technology, broad compatibility, and application versatility.

Whether you’re upgrading equipment or designing a new system, choosing the right fittings boosts safety, reduces downtime, and improves overall efficiency. Start evaluating your system today and consider upgrading to flat face fittings for reliable, leak-proof connections.

Frequently Asked Questions

- Q: What are flat face hydraulic hose fittings? Flat face hydraulic hose fittings are connectors designed to prevent fluid leakage and air inclusion, offering secure and efficient connections in high-pressure systems.

- Q: How do I start using flat face fittings? Begin by identifying your system’s pressure and compatibility needs, then select ISO-certified fittings that match your application.

- Q: How long does installation take? A standard fitting replacement takes around 15–30 minutes, depending on accessibility and experience level.

- Q: Are these fittings expensive? Prices vary based on material and brand, typically ranging from $10 to $50 per fitting. Bulk orders may reduce costs.

- Q: How do flat face fittings compare to threaded types? Flat face fittings offer quicker, cleaner connections and are generally easier to maintain, while threaded types may suit permanent or low-maintenance setups.

- Q: Are they difficult to install? With basic tools and guidance, installation is straightforward. Most setups don’t require specialized training.

- Q: Can I use them in agriculture or construction? Yes, these fittings are widely used in tractors, excavators, and other heavy-duty machinery for their durability and efficiency.