Complete Guide to Using a Fitting Bolt Effectively

Whether you’re an engineer, a contractor, or a DIY enthusiast, understanding the power and precision of a fitting bolt can transform the strength of your projects. In today’s world of complex construction and mechanical assemblies, the right fastener can mean the difference between safety and failure. This article dives deep into what fitting bolts are, how they function, where they shine, and how to apply them for maximum durability and performance.

Understanding the Fundamentals

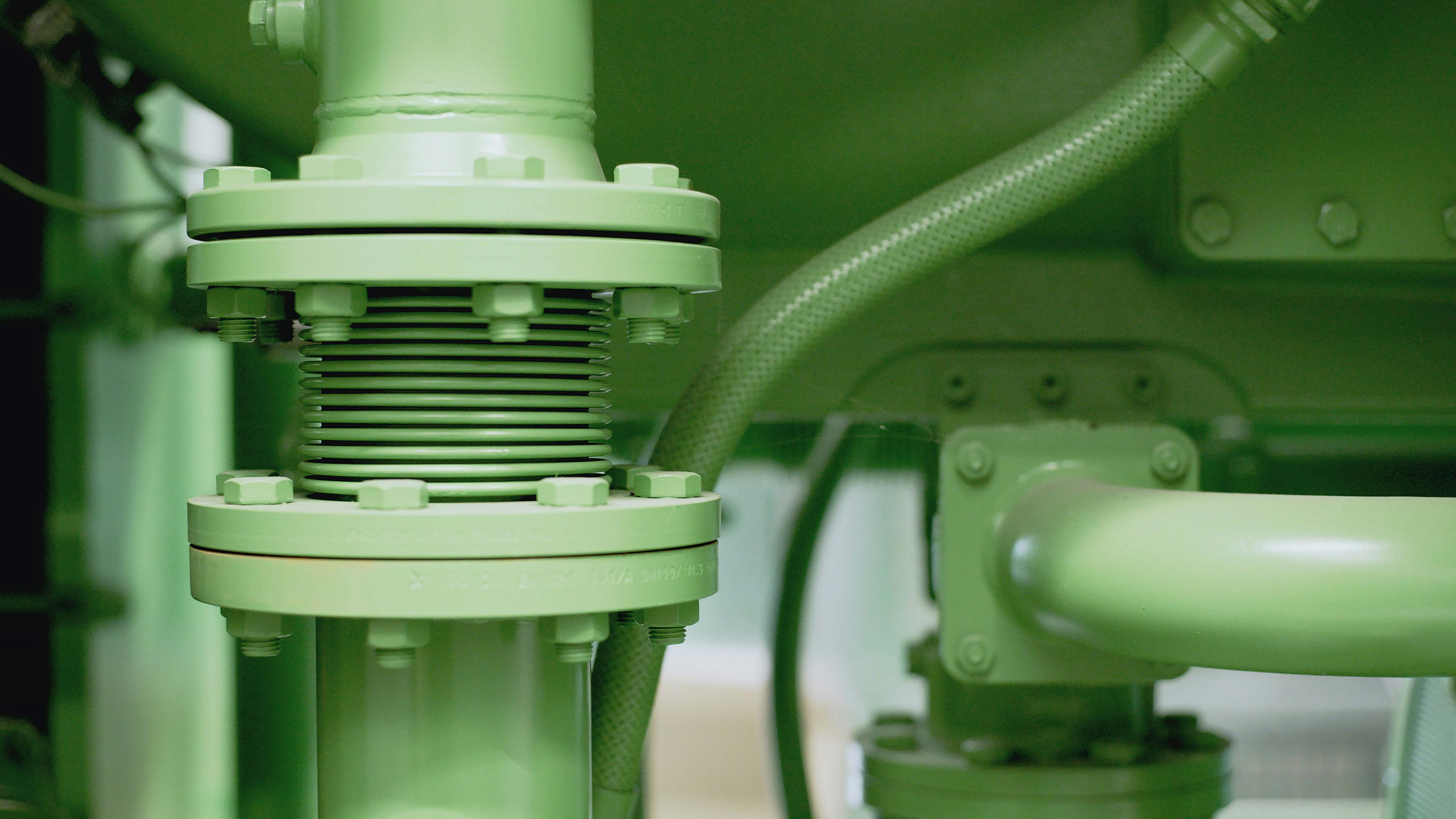

The term “fitting bolt” refers to a precision fastener designed to tightly secure two or more parts, ensuring exact alignment and structural integrity. Unlike standard bolts, fitting bolts are engineered with tighter tolerances and are typically used in scenarios where shear strength and precise alignment are critical.

Fitting bolts have evolved significantly since the early industrial era, playing a crucial role in the construction of railroads, aircraft, and modern manufacturing equipment. Their importance cannot be overstated in high-load and high-stress applications.

1.1 Precision and Tolerance

One of the defining traits of a fitting bolt is its high precision. These bolts are often machined to within microns, allowing for an exact fit into pre-drilled holes. For example, aerospace-grade fitting bolts are produced under strict specifications to ensure flight safety and mechanical stability.

In the automotive sector, precise fitting bolts are used in engine assembly where even a minor misalignment can lead to mechanical failure. Misconceptions arise when people assume fitting bolts are interchangeable with regular bolts, but their unique tolerance standards make them irreplaceable in high-spec projects.

1.2 Shear Strength vs. Tensile Strength

Fitting bolts excel in shear load resistance compared to standard bolts. While tensile strength refers to a bolt’s ability to resist being pulled apart, shear strength determines how well it holds under perpendicular force. This makes fitting bolts ideal for joints subjected to side-loading.

In steel bridge construction, for example, fitting bolts maintain alignment and resist heavy wind and traffic loads. Their application ensures minimal movement between steel plates, preserving the integrity of the structure over time.

Practical Implementation Guide

Now that we understand the mechanics behind fitting bolts, let’s explore how to effectively implement them in real-world scenarios. Proper planning, accurate measurements, and a systematic approach ensure maximum performance and safety when using these fasteners.

2.1 Actionable Steps

- Preparation: Determine bolt size and hole tolerances. Use a digital caliper to ensure accurate measurements.

- Tools and Resources: Required tools include torque wrenches, reamers, and alignment jigs. Choose high-quality fitting bolts with zinc or chrome coatings for corrosion resistance.

- Execution Timeline: A typical installation process can take 2-5 hours depending on bolt quantity and structural complexity. Always check for alignment after securing the first few bolts.

2.2 Overcoming Challenges

Fitting bolts, while reliable, can present a few challenges:

- Misaligned Holes: Ream holes if needed, but avoid over-expanding to preserve bolt fit.

- Bolt Galling: Use lubricants or anti-seize compounds to prevent thread wear.

- Stripped Threads: Never over-torque; follow manufacturer guidelines.

- Corrosion: Use weather-resistant coatings in outdoor applications.

- Fatigue Failure: Regularly inspect and retorque bolts in high-vibration environments.

Experts recommend conducting periodic maintenance checks and using thread-locking agents to extend lifespan and performance.

Advanced Applications

As projects grow in complexity, so do the requirements for fasteners. Advanced fitting bolt techniques enable higher accuracy, better durability, and enhanced safety. This section explores next-level strategies and when to adopt them.

3.1 Precision-Torqued Assembly

Precision-torqued fitting bolts are used in CNC machinery, medical devices, and aerospace engines. These bolts are installed using computer-controlled torque settings, ensuring consistent pressure and alignment. In one case study, a manufacturing firm reduced maintenance by 40% after switching to torque-calibrated fitting bolt assemblies.

3.2 Smart Fastener Integration

Smart fasteners are embedded with sensors to monitor tension, vibration, and temperature in real-time. These advanced fitting bolts are already in use in wind turbines and nuclear plants, offering predictive maintenance capabilities. Integrating these with SCADA systems helps reduce downtime and extend operational life.

Future Outlook

Technological innovation is rapidly transforming the bolt manufacturing industry. From nanocoatings to self-healing materials, the future of fitting bolts is highly promising. Industry experts forecast a 20% increase in demand for precision bolts over the next 5 years, particularly in infrastructure and aerospace sectors.

To prepare, companies and individuals should invest in training, upgrade their tools, and stay informed about new materials and installation techniques. Early adoption of smart fitting bolts will offer competitive advantages and improved safety margins.

Conclusion

Fitting bolts are far more than just mechanical fasteners—they are precision tools that guarantee alignment, strength, and durability. Three major takeaways from this guide include understanding the distinction in bolt types, mastering the installation process, and exploring future innovations.

Whether you’re upgrading machinery or building infrastructure, fitting bolts offer unmatched reliability. Start integrating them into your projects today for lasting performance. Need help selecting the right type? Consider consulting a structural engineer or bolt specialist for tailored guidance.

Frequently Asked Questions

- Q: What is a fitting bolt? A fitting bolt is a high-precision fastener used to align and secure mechanical parts under strict tolerances.

- Q: How do I get started with fitting bolts? Begin by identifying the load type and selecting the appropriate bolt grade, followed by accurate hole preparation.

- Q: How much time does installation take? It can range from 2 to 5 hours depending on application complexity and number of bolts used.

- Q: Are fitting bolts expensive? Prices vary based on material and coating, typically ranging from $0.50 to $5 per bolt for general use.

- Q: How do fitting bolts compare to regular bolts? They offer tighter tolerances and better shear strength, making them ideal for precision assembly.

- Q: Are they difficult to install? Installation is straightforward with the right tools and preparation. Some training is beneficial for high-spec jobs.

- Q: Can they be used in automotive or aerospace applications? Absolutely—fitting bolts are commonly used in engines, gear assemblies, and airframes for safety and precision.