Comprehensive Guide to Flowline Pipe Fittings

Flowline pipe fittings are the unsung heroes of industrial piping systems. As industries expand and demand more efficient systems, understanding how these fittings work has never been more important. In this guide, you’ll discover what flowline pipe fittings are, how they function, where they’re used, and how to implement them effectively across various sectors.

Understanding the Fundamentals

Flowline pipe fittings are essential components used to connect, redirect, and control the flow of liquids and gases through pipelines. Whether in oil and gas, water systems, or chemical industries, these fittings form the backbone of safe and efficient operations. Their role has evolved significantly with advancements in pressure technology and flow control mechanisms.

Grasping the basics of flowline pipe fittings allows for smarter engineering decisions. Just like a strong spine supports a body, these fittings support entire pipeline infrastructures by ensuring pressure integrity, durability, and seamless connectivity.

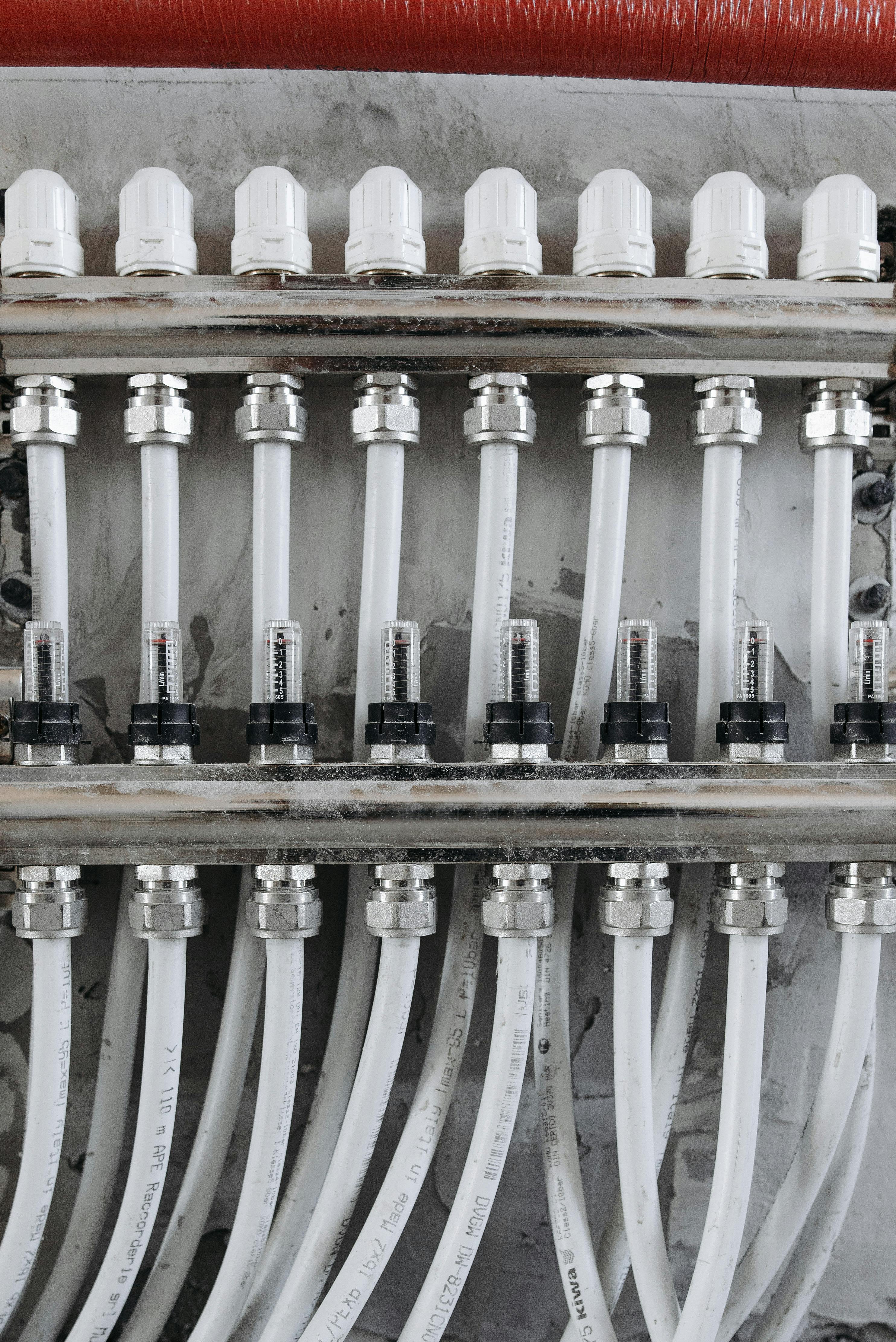

1.1 Core Components and Functions

Flowline pipe fittings include elbows, tees, reducers, couplings, and flanges. Each type serves a specific function:

- Elbows change direction

- Tees divide or combine flows

- Reducers adjust flow diameter

- Couplings connect straight pipe sections

- Flanges provide disassembly access

Modern flowline pipe fittings are designed to withstand high pressures and corrosive environments. According to recent industry surveys, nearly 75% of pipeline failures are due to improper fitting selection—highlighting the importance of choosing the right components.

1.2 Material and Pressure Considerations

Flowline pipe fittings differ based on the material—carbon steel, stainless steel, and specialty alloys are most common. Each material offers a different strength profile, cost, and corrosion resistance level.

For instance, carbon steel is ideal for high-pressure gas transmission, while stainless steel suits sanitary and chemical environments. Knowing the medium being transported helps in selecting the most appropriate material type.

Practical Implementation Guide

After grasping the fundamentals, the next step is application. Flowline pipe fittings are not one-size-fits-all; they require proper planning and execution to ensure safety and longevity. Successful implementation starts with assessing system pressure, medium, flow direction, and maintenance needs.

2.1 Actionable Steps

- System Design: Map out pipeline dimensions, bends, and joints based on flow requirements and spatial constraints.

- Select Components: Choose pipe fittings rated for your pressure range and medium. Use industrial catalogs or CAD modeling tools to visualize connections.

- Install and Test: Install the fittings using certified personnel. Conduct hydrostatic and pneumatic pressure tests before full operation.

2.2 Overcoming Challenges

Common obstacles include misaligned fittings, leakage, incompatible materials, and corrosion. Watch out for signs like pressure drops or visible rusting near joints.

To troubleshoot:

- Use laser alignment tools for precision

- Apply anti-corrosion coatings

- Double-check torque specs during flange tightening

Advanced Applications

Beyond basic connections, flowline pipe fittings are crucial in high-performance and mission-critical systems. Industries like aerospace, deep-sea exploration, and high-pressure oil drilling rely heavily on specialized fitting designs. Knowing when and how to use advanced fittings can greatly enhance operational resilience.

3.1 Precision Flow Control Systems

High-precision pipe fittings are used in control systems that regulate pressure and flow within ±1% accuracy. These systems are often found in chemical processing and pharmaceutical plants. Case studies show a 20% reduction in waste and 30% increase in efficiency when precision fittings are used over conventional ones.

3.2 Integration with Digital Monitoring

Smart flowline systems integrate IoT sensors to monitor pressure, temperature, and flow rate in real time. These fittings are compatible with SCADA systems, enhancing automation and preventive maintenance efforts.

When integrating these systems, ensure sensor-compatible fittings are chosen, with access ports and data relay options built-in.

Future Outlook

The future of flowline pipe fittings lies in smart technology and eco-friendly materials. Trends indicate a surge in demand for composite fittings that combine strength with lightweight design. AI-driven leak detection and self-healing materials are also under development.

Over the next 3-5 years, expect a significant shift toward digital integration, real-time diagnostics, and sustainability-driven designs. Adopting these innovations early positions companies for long-term success.

Conclusion

To summarize:

- Flowline pipe fittings are vital for system integrity and performance

- Material selection and application technique determine longevity

- Advanced systems and smart integration open up new possibilities

Understanding and properly implementing flowline pipe fittings can dramatically improve operational efficiency and safety. Now is the time to evaluate your system needs and upgrade accordingly.

Get started by assessing your current pipeline setup today—invest in better fittings for a more reliable tomorrow.

Frequently Asked Questions

- Q: What are flowline pipe fittings? Flowline pipe fittings are components used to connect or control the direction and flow of liquids or gases in pipelines. They include elbows, tees, reducers, and flanges.

- Q: How do I choose the right fittings to start with? Start by identifying your flow medium, pressure requirements, and environment. Then match these with fitting material and design specifications.

- Q: How long does it take to install a fitting system? Basic installations take a few hours, but complex systems may require several days including testing and calibration.

- Q: How much do flowline pipe fittings cost? Costs vary widely. Standard steel fittings range from $5 to $50 each. Specialized high-pressure or sensor-equipped types can exceed $200 per unit.

- Q: Are there alternatives to flowline fittings? Yes, flexible hose systems or welded pipe joints are alternatives, but they often lack the modularity and ease of maintenance flowline fittings offer.

- Q: Are these fittings difficult to install? Not typically. With the right tools and training, installation is straightforward. However, high-pressure systems do require expert handling.

- Q: How are flowline fittings used in the oil and gas industry? They’re used for wellhead assemblies, pipeline transitions, and fluid control systems, ensuring pressure integrity and flow optimization in harsh environments.