Mastering Hydraulic Hose Fitting Assortment Techniques

In today’s industrial world, efficiency and reliability are paramount. Hydraulic hose fitting assortment plays a critical role in ensuring smooth operations across countless industries. This guide offers a deep dive into understanding, applying, and optimizing hydraulic hose fittings for professionals and DIY enthusiasts alike.

Understanding the Fundamentals

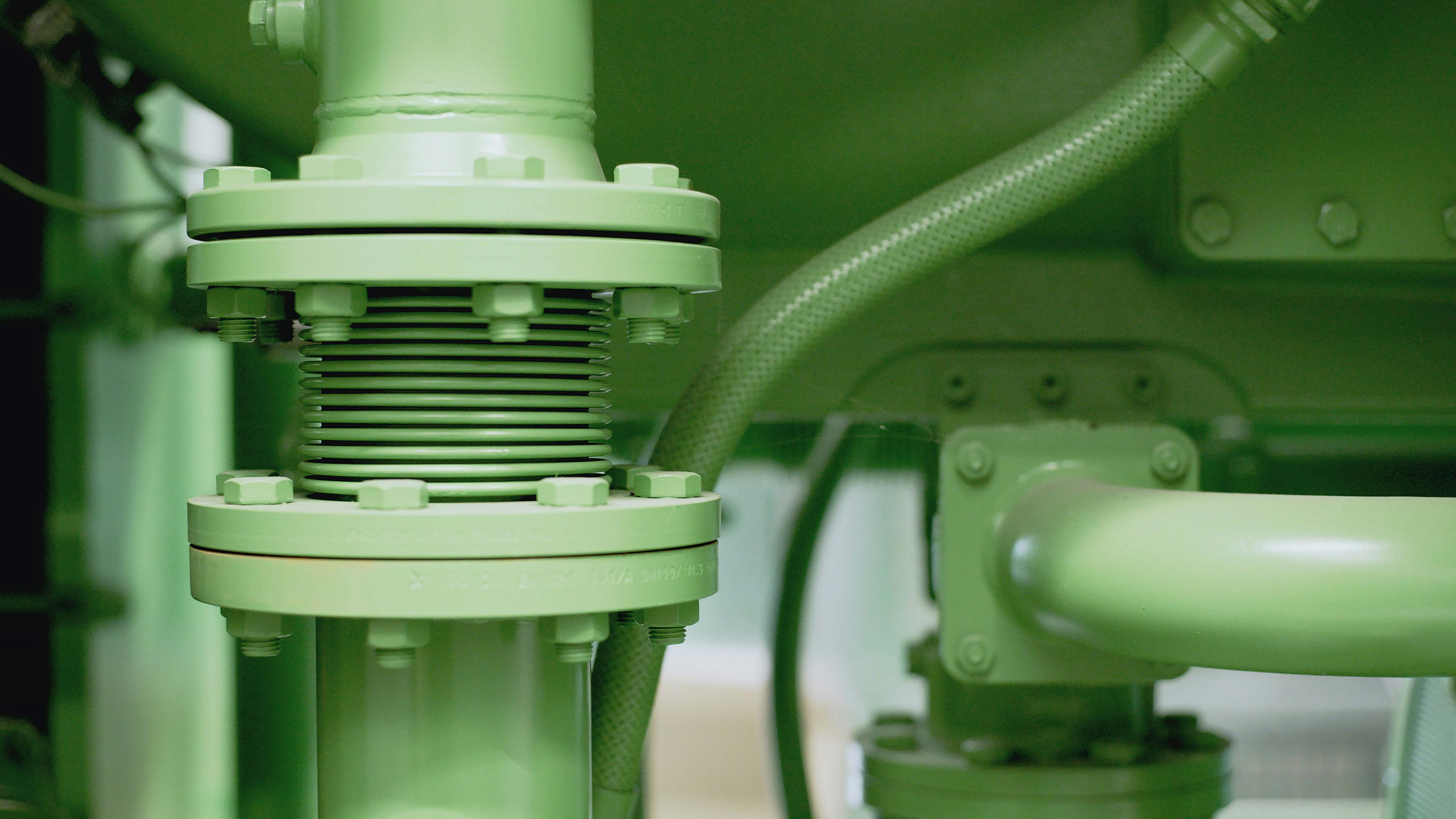

Hydraulic hose fitting assortment refers to the collection of different types and sizes of connectors used to join hydraulic hoses and ensure leak-proof fluid transmission. This concept is vital in systems where hydraulic pressure must be safely managed. Over the decades, the development of fittings has paralleled advancements in machinery and automation.

By understanding the fundamentals of hydraulic hose fittings, you gain control over fluid direction, pressure containment, and equipment longevity. Imagine your hydraulic system as a human body—fittings act like joints, keeping all limbs connected and functional.

1.1 Types of Hydraulic Hose Fittings

Hydraulic fittings generally fall into categories such as compression, flare, crimp, and reusable fittings. Compression fittings are ideal for low-pressure settings, while crimp and flare fittings excel in high-pressure applications. According to recent studies, crimp fittings now dominate over 70% of industrial hydraulic connections due to their reliability.

These fittings are commonly used in manufacturing plants, construction sites, and agricultural equipment. However, one frequent misconception is that all fittings are interchangeable—this is rarely the case due to thread type, pressure rating, and application-specific designs.

1.2 Key Connection Standards

Two of the most common standards in hydraulic hose fitting assortment are SAE and ISO. While SAE fittings are widely used in North America, ISO fittings are more common globally. Their main differences lie in thread design and pressure capacity.

For example, an SAE JIC 37° flare fitting is often used in high-performance hydraulic systems like aerospace, while BSP fittings (British Standard Pipe) are favored in marine and agricultural industries due to their sealing reliability and corrosion resistance.

Practical Implementation Guide

Once you’ve grasped the fundamentals, the next step is effective implementation. Selecting the right hydraulic hose fitting assortment ensures that your system operates safely and efficiently. Expect improved machine longevity, minimal downtime, and easier maintenance routines.

2.1 Actionable Steps

- Identify System Requirements: Assess the pressure, fluid type, and temperature range the system will operate in.

- Select Compatible Fittings: Match hose and fitting sizes accurately. Use calipers or sizing charts to avoid misalignment.

- Test Before Use: Perform a pressure test on the assembled system to detect potential leaks or fitting failure.

2.2 Overcoming Challenges

Common issues include thread mismatches, incorrect torque application, and fluid compatibility errors. Watch out for leaks, hose bulging, or whistling sounds as early warning signs. Each of these can signify an improper hydraulic hose fitting assortment.

Experts recommend color-coding or labeling your fittings by pressure rating or function. Also, always store your fittings in a clean, moisture-free environment to prevent rust or contamination.

Advanced Applications

When your hydraulic system grows in complexity, it’s time to leverage advanced fitting techniques. These include quick-connect fittings, swivel adapters, and multi-line manifolds. Such methods are essential in mobile equipment, robotic arms, and mining operations where rapid assembly and disassembly are routine.

3.1 Quick-Connect Systems

Quick-connect fittings allow rapid changeover without tools, minimizing system downtime. They’re widely used in forklifts, snowplows, and industrial presses. Case studies show that companies using quick-connect systems experience a 25% reduction in maintenance time.

3.2 Swivel and Rotating Fittings

Swivel fittings reduce hose twist, which extends lifespan. These are ideal in dynamic systems like excavators and rotating arms. Before integrating them, ensure compatibility with your current hydraulic hose fitting assortment to avoid torque stress or leaks.

Future Outlook

As automation and AI continue to grow, smart hydraulic systems are on the rise. These incorporate sensors and IoT devices to monitor pressure, temperature, and wear in real-time. The demand for modular fittings and sustainable materials like stainless steel and composite blends is expected to surge.

Preparing now involves upgrading to fittings that support digital monitoring and training staff on new standards. Within 3-5 years, adaptive hydraulic systems may become the industry norm.

Conclusion

Hydraulic hose fitting assortment is the backbone of safe, efficient fluid power systems. Key takeaways include: selecting fittings based on pressure and fluid type, regularly inspecting for wear, and leveraging advanced fittings for complex systems.

Start evaluating your current setup today. Consider a professional fitting audit or invest in a starter assortment kit to streamline your operations.

Frequently Asked Questions

- Q: What is a hydraulic hose fitting assortment? It’s a curated collection of various hydraulic connectors used to link hoses in fluid power systems.

- Q: How do I get started with choosing the right fittings? Begin by assessing system pressure, hose size, and fluid compatibility, then consult a sizing chart.

- Q: How long does installation usually take? For small systems, 30-60 minutes; complex systems may take several hours depending on layout and access.

- Q: How much do these fittings cost? Prices range from $2–$40 per fitting depending on material, size, and type. Bulk kits can cost $100–$500.

- Q: How do hydraulic fittings compare to push-to-connect options? Hydraulic fittings handle higher pressure but require tools; push-to-connect fittings are quicker but for lower-pressure systems.

- Q: Are hydraulic fittings difficult to install? With the right tools and instructions, most fittings are straightforward. Crimp fittings may require specialized machines.

- Q: Can I use these fittings in marine or agricultural settings? Absolutely—just choose corrosion-resistant materials like stainless steel or brass designed for your specific industry.