Mastering Hydraulic Tank Fittings for Reliable Systems

Hydraulic tank fittings play a crucial role in maintaining the integrity and efficiency of hydraulic systems. As modern industries grow increasingly dependent on fluid power, understanding how these fittings operate can significantly improve performance and reduce maintenance costs. In this comprehensive guide, we’ll explore the core principles, practical installation methods, advanced techniques, and future innovations tied to hydraulic tank fittings.

Understanding the Fundamentals

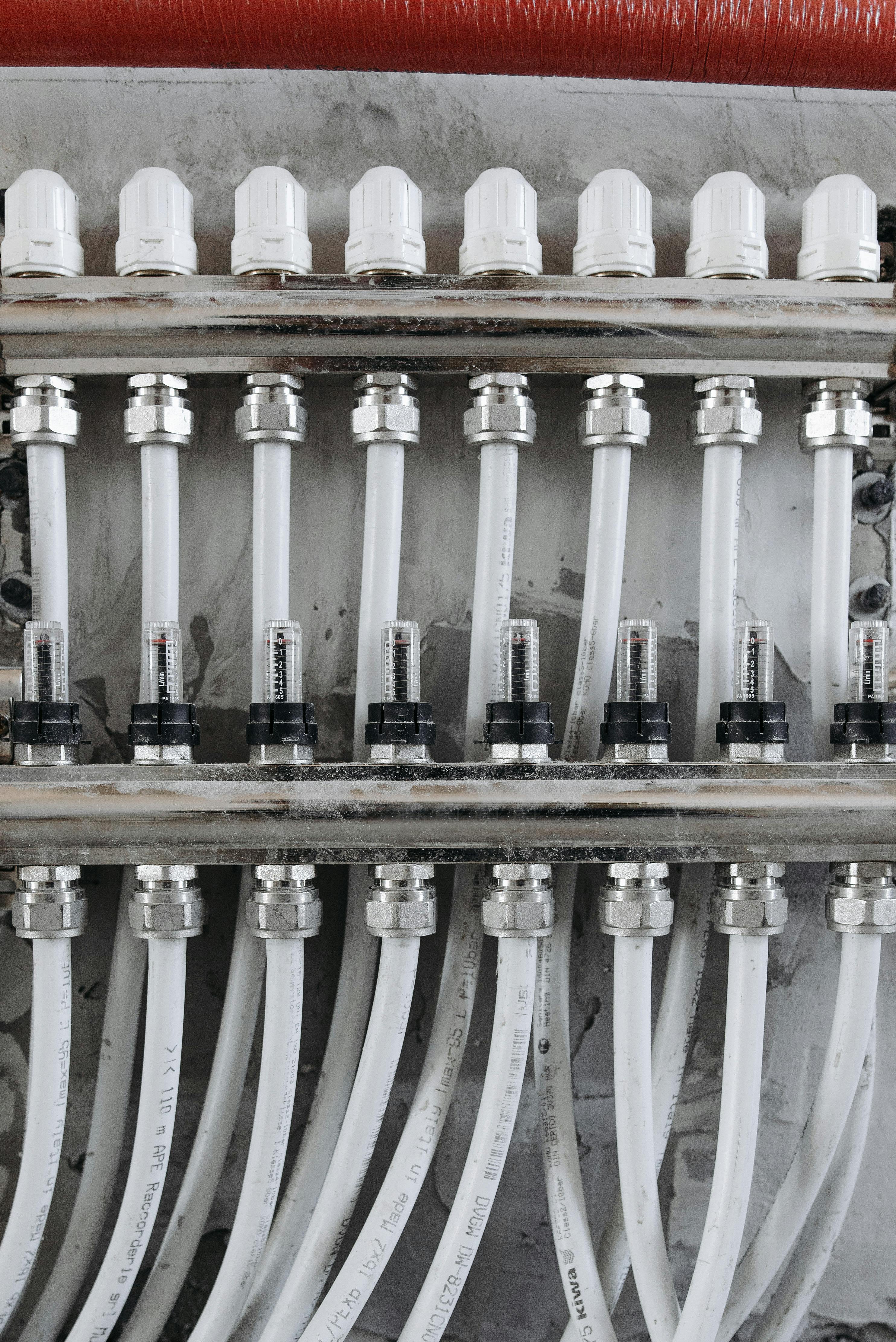

Hydraulic tank fittings are connectors used to join the reservoir of hydraulic fluid with various system components. Their primary function is to ensure leak-proof, high-pressure connections that withstand both static and dynamic loads. These fittings are essential for fluid conveyance, system efficiency, and pressure containment.

Historically, hydraulic systems have evolved from simple mechanical pumps to intricate networks driven by computer-controlled valves. This evolution has elevated the importance of selecting the right hydraulic tank fittings tailored to specific operational demands.

1.1 Pressure Management

Proper fittings help maintain system pressure by minimizing leaks and ensuring seamless flow. They are built to handle a wide range of pressures, from low-pressure return lines to high-pressure output systems, commonly seen in manufacturing and heavy machinery.

In fact, poorly selected or installed fittings are among the leading causes of pressure loss and equipment failure. Understanding the pressure rating and compatibility of fittings with hoses and tanks is critical.

1.2 Material and Design Compatibility

Hydraulic tank fittings come in materials like brass, steel, stainless steel, and composite polymers. Each material offers distinct benefits—stainless steel, for instance, excels in corrosion resistance, making it ideal for marine or chemical processing applications.

Designs vary as well, including straight, elbow, tee, and flange styles. Choosing the right design affects not just flow efficiency but also the physical layout and serviceability of the system.

Practical Implementation Guide

After grasping the basics, the next step is applying this knowledge in the field. Proper implementation ensures both safety and durability. Whether you’re installing new hydraulic lines or upgrading existing components, following a structured approach is essential.

2.1 Actionable Steps

- Assessment: Identify flow requirements, pressure ratings, and material compatibility with hydraulic fluid.

- Selection: Choose the correct hydraulic tank fittings based on design, thread type, and seal integrity.

- Installation: Use torque specifications to tighten fittings correctly, avoiding over-tightening or thread stripping.

2.2 Overcoming Challenges

Common challenges include thread mismatches, corrosion, vibration-induced loosening, and compatibility issues. To overcome these:

- Use thread sealants designed for hydraulic applications.

- Employ anti-vibration clamps where necessary.

- Opt for fittings with O-ring face seals to minimize leak risks.

Monitoring systems for early signs of wear—like fluid seepage or pressure drops—helps prevent bigger failures. Experts recommend routine checks and pressure testing every six months for high-usage systems.

Advanced Applications

Beyond standard configurations, hydraulic tank fittings are pivotal in high-performance and specialty applications. From aerospace to precision robotics, these fittings must meet strict standards of accuracy, durability, and heat resistance.

3.1 Multi-Port and Custom Fittings

Multi-port fittings are used in complex systems requiring multiple fluid paths. These are common in high-capacity equipment like excavators or hydraulic presses. With advanced CAD design, fittings can be custom-built to meet unique spatial and performance needs.

Performance data from leading manufacturers indicate that custom fittings reduce system failure rates by up to 22% compared to standard parts in specialized environments.

3.2 Smart Integration

Today’s hydraulic systems often integrate sensors and IoT elements directly into fittings. These smart fittings can relay pressure, temperature, and flow data in real-time, improving predictive maintenance and automation capabilities.

Compatibility is key here—ensure that fittings meet ISO standards and are certified for the desired integration platform. It’s also essential to protect wiring and sensors from environmental damage.

Future Outlook

As industries continue adopting smarter and greener technologies, hydraulic tank fittings are also evolving. Trends include lightweight composite fittings, bio-fluid compatibility, and AI-driven diagnostics. These innovations promise reduced downtime and improved system intelligence.

Over the next 3–5 years, expect more widespread adoption of smart fittings and increased focus on sustainability. By staying informed and investing in compatible infrastructure today, businesses can future-proof their hydraulic systems.

Conclusion

To summarize, understanding the types and roles of hydraulic tank fittings is essential for any fluid-powered system. Proper material selection, correct installation techniques, and strategic use of advanced fittings can greatly extend system life and efficiency.

If you’re planning a new installation or looking to upgrade your hydraulic system, now is the time to assess your fittings. Reach out to industry suppliers or certified engineers to ensure your choices align with both operational goals and safety standards.

Frequently Asked Questions

- Q: What are hydraulic tank fittings? Hydraulic tank fittings connect the fluid reservoir to other components in a hydraulic system, enabling leak-free and efficient flow of hydraulic oil.

- Q: How do I start selecting the right fitting? Begin by identifying your system’s pressure range, fluid type, and space limitations, then consult a fitting chart or a professional supplier.

- Q: How long does installation take? Simple installations take 30–60 minutes, while complex systems may require 3–4 hours or more depending on layout and testing.

- Q: Are hydraulic fittings expensive? Prices range from $5 for basic brass fittings to $100+ for high-pressure stainless steel or smart fittings. Cost varies with size, material, and precision.

- Q: How do hydraulic fittings compare to pneumatic? Hydraulic fittings handle higher pressures and use oil-based fluids, while pneumatic systems use compressed air and operate at lower pressures. Hydraulics offer more power.

- Q: Are these systems difficult to work with? Basic hydraulic systems are manageable with proper tools and training. Advanced systems require specialized knowledge and safety precautions.

- Q: Can hydraulic fittings be used in agriculture? Absolutely. Agricultural equipment like tractors and harvesters use hydraulic systems for tasks like lifting, plowing, and seeding, requiring durable tank fittings.