Mastering the Hydraulic Grease Fitting: Complete Guide

When it comes to efficient machinery maintenance, the hydraulic grease fitting plays a crucial role. Understanding its purpose and function can significantly extend the life of your equipment and ensure smooth operations. In this guide, you’ll learn everything from the fundamentals to advanced applications of grease fittings, empowering you to optimize your lubrication systems and avoid costly downtime.

Understanding the Fundamentals

The hydraulic grease fitting, also known as a Zerk fitting, is a small but mighty component used to lubricate mechanical parts under pressure. Introduced in the 1920s, this fitting allows grease guns to inject lubricant directly into bearing housings and joints.

Mastering the use of grease fittings is essential for preventive maintenance. Like the valve on a tire that lets air in but not out, these fittings allow grease to enter sealed areas without leakage or contamination.

1.1 The Function of a Hydraulic Grease Fitting

A hydraulic grease fitting functions as a one-way valve. It enables pressurized grease to flow into machine components while blocking contaminants from entering. Common in automotive, agricultural, and industrial equipment, it’s indispensable for protecting moving parts from wear.

For example, heavy-duty equipment like excavators or tractors often contain over 100 fittings, each requiring regular lubrication to prevent seizing and extend machinery life.

1.2 Why Proper Lubrication Matters

Without proper lubrication, friction causes heat, which degrades machine parts and leads to mechanical failure. Hydraulic grease fittings ensure that grease reaches critical areas efficiently, even under high pressure.

By regularly applying grease through these fittings, operators maintain smoother equipment motion, reduce maintenance costs, and minimize the risk of part replacement.

Practical Implementation Guide

Once you understand how grease fittings work, the next step is to implement a consistent maintenance routine. Whether you’re a technician or a DIY mechanic, applying best practices makes a significant difference in machinery lifespan.

2.1 Actionable Steps

- Inspect Equipment: Identify all grease points using the machinery manual or inspection chart.

- Use the Right Grease Gun: Ensure compatibility with your hydraulic grease fittings. Lever and pistol-grip styles are common.

- Apply Grease Correctly: Wipe the fitting clean before connecting the grease coupler. Pump until old grease purges from seals.

2.2 Overcoming Challenges

Grease fitting maintenance isn’t without challenges. Here are common issues:

- Blocked fittings — use a needle adapter or replace if clogged

- Leaky couplers — switch to a locking grease coupler for a tighter seal

- Inaccessible locations — use flexible hoses or right-angle adapters

Experts recommend tagging inaccessible or worn-out fittings during inspections to ensure they aren’t missed during routine lubrication.

Advanced Applications

As you refine your maintenance strategy, advanced techniques can enhance your results. These involve high-pressure systems, automated lubrication, and specialized fittings that extend service intervals and reduce labor time.

3.1 High-Pressure Systems

Some industrial applications require grease to be applied at pressures exceeding 10,000 PSI. In such cases, high-pressure grease guns and fittings are essential. These systems are common in mining and heavy manufacturing environments where standard fittings would fail.

Case studies from the aerospace industry show that high-pressure lubrication reduces downtime by up to 30%, significantly improving operational efficiency.

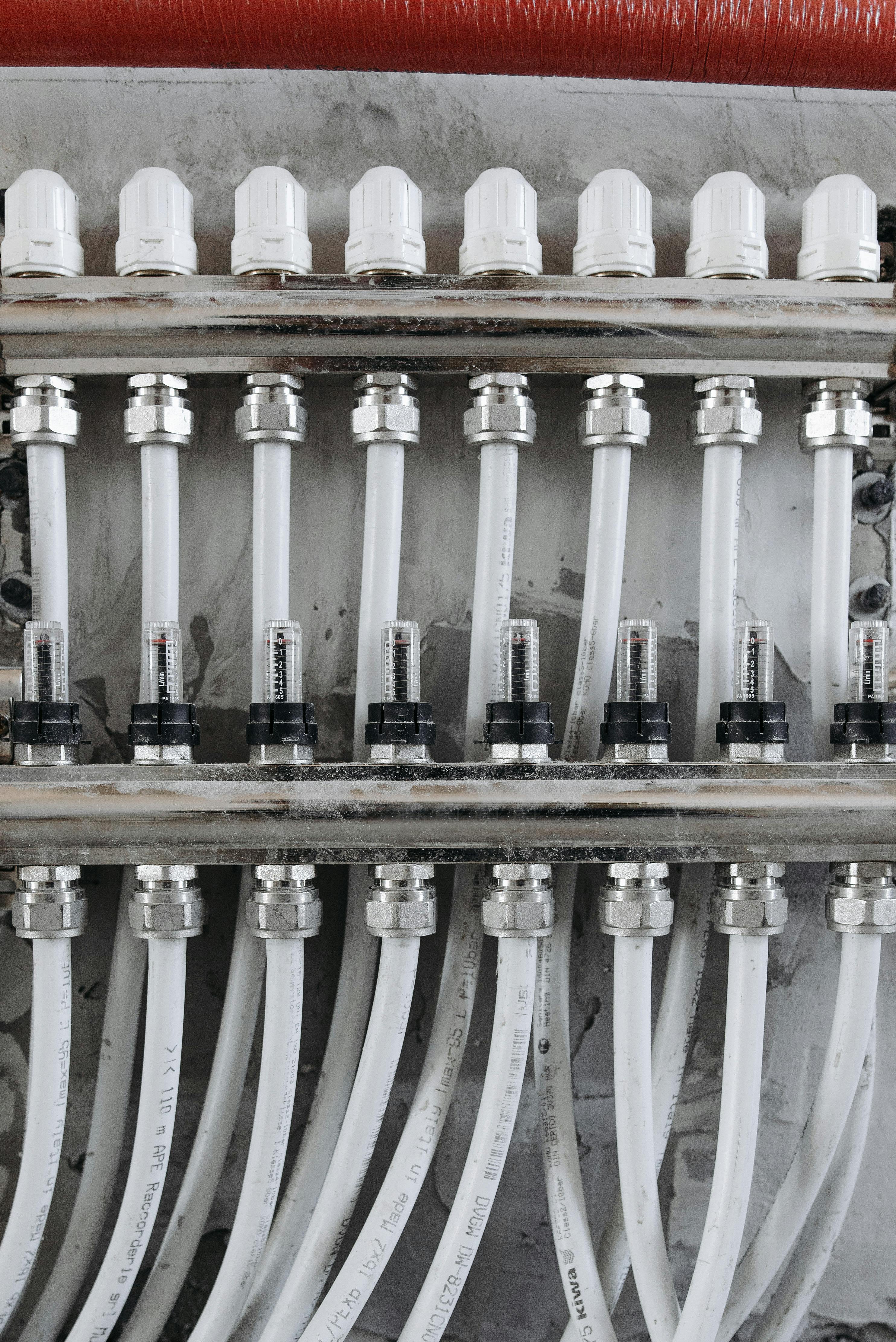

3.2 Centralized Lubrication Systems

Modern factories are adopting centralized lubrication systems that connect multiple grease fittings through tubing and valves. These systems allow for simultaneous lubrication, saving time and ensuring consistency.

However, these setups require careful calibration and are typically integrated into machinery during manufacturing or major overhauls.

Future Outlook

The hydraulic grease fitting may seem like a static technology, but it’s evolving. Smart fittings with sensors are emerging, enabling predictive maintenance via IoT devices. These innovations help anticipate lubrication needs and reduce human error.

Experts predict that within five years, over 60% of industrial equipment will include digital grease monitoring, driven by the demand for data-driven asset management.

Conclusion

Understanding and maintaining your hydraulic grease fittings is a foundational aspect of equipment care. From proper lubrication to advanced integration, these components keep your systems running smoothly.

Whether you’re a hobbyist or maintenance supervisor, adopting a structured lubrication routine improves machine life, reduces downtime, and saves costs. Start your maintenance schedule today to reap long-term benefits.

Frequently Asked Questions

- Q: What is a hydraulic grease fitting? A hydraulic grease fitting is a valve-like component that allows grease to be injected into mechanical parts under pressure without letting contaminants in.

- Q: How do I get started with using grease fittings? Begin by identifying all grease points, acquiring the proper grease gun, and setting a regular maintenance schedule.

- Q: How much time does lubrication take? Basic greasing takes 15–30 minutes depending on equipment complexity, but centralized systems can reduce this dramatically.

- Q: What does it cost to maintain grease fittings? Manual maintenance costs under $50 in tools and supplies, while automated systems can range into thousands for large installations.

- Q: Are hydraulic grease fittings better than sealed bearings? Each has its use. Fittings allow re-lubrication, which extends life, while sealed bearings are maintenance-free but finite in lifespan.

- Q: How hard is it to replace a fitting? It’s a simple task requiring only a wrench and replacement Zerk fitting, usually done in under 5 minutes.

- Q: Are grease fittings used in the food industry? Yes, stainless steel fittings and food-grade grease are used in processing equipment to maintain hygiene and compliance.